Sewing Machine Needle Sizes – A Basic Guide

A needle is an indispensable tool and component for any sewing machine. It will affect your sewing techniques, efficiency, and the project’s beauty. Therefore, understanding the machine’s needle size is critical.

To bring the highest result, you must select the suitable sewing machine needle sizes for the type of fabric and thread. In this post, I will discuss the basics of sewing machine needle sizes to give you a straightforward answer.

Table of Contents

Parts Of A Sewing Needle

Most sewing machine needles come with essential components like a shank, shaft, groove, and needlepoint. These parts’ dimensions and designs will decide the size of the needle you use.

Therefore, I will briefly describe each component and give you a detailed look at the sewing machine’s needle before dwelling on the different needle sizes.

Shank

Shank is a thick part located on the upper side of the needle, which attaches to the machine. The shank usually has a round side and a flat side, which helps the sewer position the needle easier.

However, most needles used for industrial sewing machines are entirely round. Sewers will resort to their grooves and determine the proper direction to place in the needle.

If you have a problem attaching the needle to the machine, check out the owner’s manual and follow the proper instructions.

Shaft

The area between the needle’s bottom and its point is called the shelf. You can look for the needle’s groove and the other components like the eye, scarf, and the needle’s point.

Groove

The groove runs along the needle’s body. It serves as a spot to lay the thread into the needle. Rather than searching with their eyes, sewers can use their fingernails to feel the groove.

Scarf

There’s a minor groove on the side of the needle called the scarf. It’s where the upper thread and bobbin case intersects, thus forming the sewing stitches when the machine operates.

Eye

The needle’s eye’s function is to carry the thread and help form the stitches when a sewing machine operates. Without this component, the machine cannot continuously make stitches and will get interrupted.

Similar to the groove and shaft, the needle’s eye also varies in size, depending on the type of sewing machine you use. The eye size often pairs in conjunction with the needle’s groove.

Using a broken needle part with improper eye and groove sizes will shred or even damage your thread. Therefore, it’s essential to check and maintain the needle’s components regularly when sewing garment projects.

Related:

– Who Invented the Sewing Machine?

– How to end a Stitch?

Point

Point is the end part of a needle where it contacts the fabric material. The shape and design of the point will decide how you sew and thread the fabric garment.

There are three popular point designs, including ballpoint, sharp, and universal.

The needles with a sharp point are ideal for sewing woven fabric and straight lines due to their minimum contact area and higher tension. Meanwhile, ballpoint needles are a prevalent choice for sewing knit fabric.

If you use regular sharp needles, the needle point can easily damage the fabric fibers when it’s moving between the knit fabric loops. However, a ballpoint needle cannot deliver as straight and even stitches as sharp points.

Another prevalent choice is the universal point, which can be applied to both knitting and woven fabric. It features a rounded point, but still ensures sufficient sharpness to sew the woven fabric efficiently.

Sewing Machine Needle Sizes

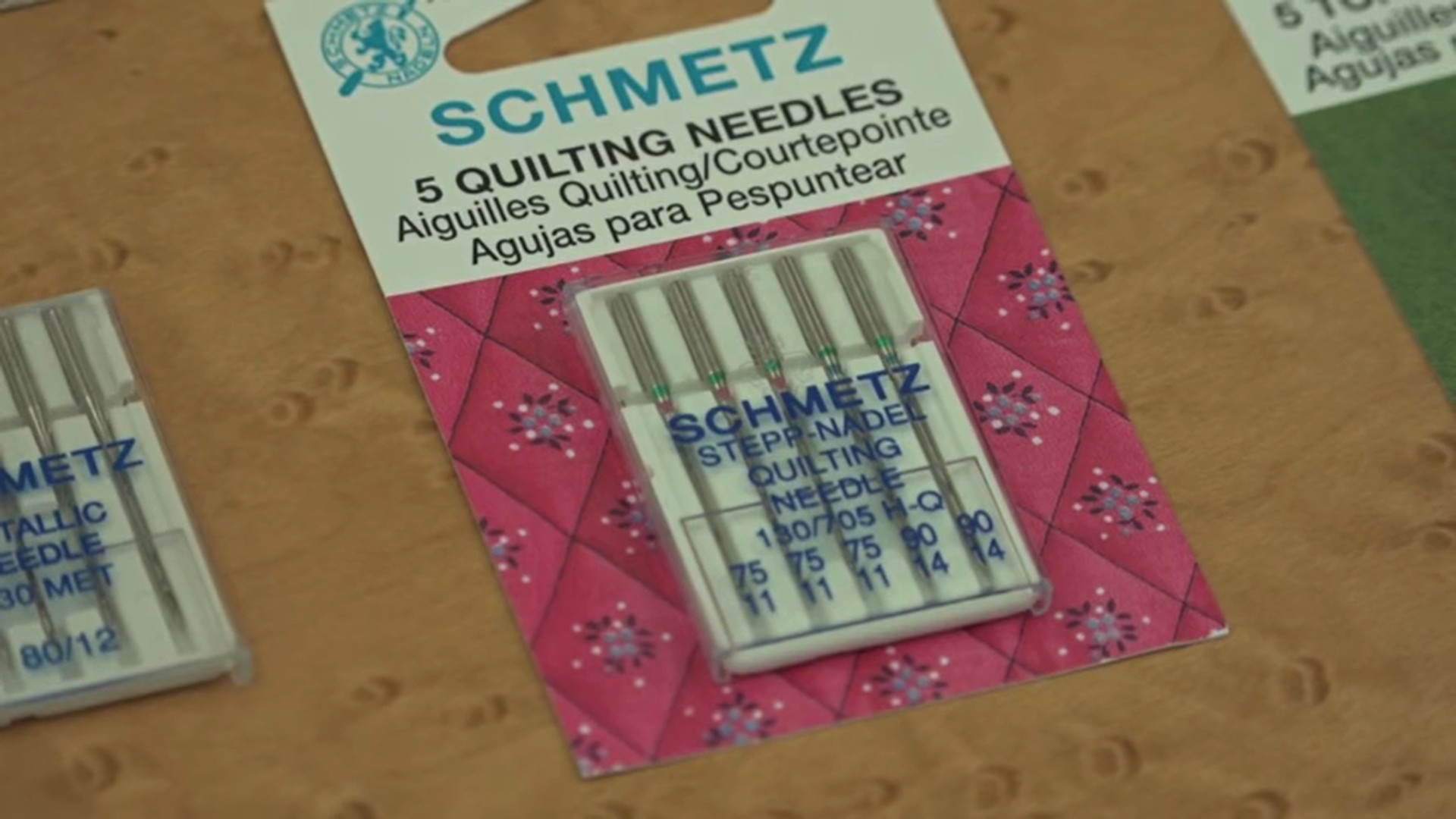

The sewing machine needle sizes are often accompanied by numbers ranging between 8 and 19 or 60 and 120, depending on the system. Understanding those numbers will help you choose the proper needle size.

The European sewing industry uses numbers between 60 and 120 to address sewing machine needle sizes. Meanwhile, the number for the American system ranges between 8 and 19.

A higher number equals a heavier and thicker needle’s size, and this rule applies to all number systems. For example, an eight needle is the smallest needle size in America, while 19 is the largest and heaviest needle.

For small and lean fabric textures such as a window curtain, you only need a small needle (around 8 or 60 in the two systems). Using larger needle sizes will damage the curtain fabric structure and ruin its aesthetic look.

On the other hand, a thick and heavy needle (around 17 or 100 in size) is ideal for sewing upholstery fabric. The 8-needle is simply too lean and weak to penetrate the fabric material.

So, what to do when you want to sew a lightweight garment, but it requires heavy thread and stitches on the surface? Using a 19-needle point will ruin the fabric texture with large holes on its surface.

The right choice should be a medium-sized needle (around 12 or 90). These general rules only help sewers target the suitable needle range for each fabric material by evaluating their texture, weight, and thickness.

You need to experiment with each needle size carefully before threading them to pick the perfect size. Choosing the wrong needle size for different sewing projects is a common mistake that no sewer can avoid.

In the following sections, I will list some popular sewing needle sizes and their compatible thread or fabric materials. Let’s check them out to know which is the perfect needle size for your projects.

Self-Threading Or Handicap Needles?

The self-threading or handicap needles are excellent for beginners and disabled people who cannot thread a needle. These needles’ slits are put very close to your eye depending on the needle’s size.

The sewers can slowly slide the thread on the needle’s size. From this point, it will slowly slide and fit into the eye. These needles can serve multiple purposes thanks to their high utility and user-friendly design.

These needles are inexpensive and available in any sewing accessory store. However, a self-threading needle is not available in all sizes, unlike a regular one. You can only find these tools between 12 and 14 or 80 and 90.

Another setback is that the thread can easily slide off the needle when sewing if you pull it with too much force. In addition, sewers have to stabilize the needle to avoid losing the thread constantly.

Related: How to use a Walking Foot?

Triple And Twin Sewing Needles

Triple and twin sewing needles are one of the most common and indispensable tools for creating decorative patterns on fabric garments. These needles have a crossbar that connects them to a single shank.

This design makes the triple and twin sewing needles perfect for tight sewing stitches in even rows. However, only sewing machines that support the zig-zag sewing pattern are compatible with triple and twin needles.

Due to their large points, the machine needs to have a wide hole to place in the needles. Also known as drilling needles, the triple and twin sewing needles have an additional number that indicates the distance between the two needles.

Stretch Needles

As their name suggests, stretch needles come with stretch points with very high flexibility and durability. A stretch needle is the best choice if you want to sew stretchy fabric materials.

Some examples are elastic materials, stretchy knits, and swimwear. Most stretch tools have a shorter eye than the regular needles, plus a flat shank and a deep scarf.

The tool’s ballpoint is medium in size and has a special coating outside to help the point glide on slippery fabric surfaces. This tool can challenge even the stretchy fabric garments you can find.

Wing Needles

The wing needles on sewing machines can create an eyelet effect on the garment project. There are two small flanges on the two sides of the needle that separate the fiber and create a hole in the fabric.

Wing needles are available in various sizes to suit the fabric weights and materials. A wing needle with a larger size can create larger holes in the garment and vice versa.

These tools are also called hemstitching needles, as sewers commonly use them on the borders and hems. They are also ideal for decorative sewing patterns on pillowcases, handkerchiefs, towels, and other woven fabric pieces.

Leather Sewing Needles

People also call a leather sewing needle the chisel point since its point looks like a chisel when the machine is running. As its name suggests, you should use these tools to sew high-quality and genuine leather fabric garments.

A leather sewing needle is also compatible with suede and other challenging materials. However, it won’t deliver great results on PU and other artificial leathers due to their different fiber structure.

Denim/Jeans Sewing Needles

These needles usually come with a very sharp point to pierce the thick and heavy surface of jeans or denim. In addition, their shanks have to be very stiff, so they won’t break when sewing these thick materials.

You can also use jean sewing needles on other woven fabric types like canvas, heavy linen, and twill. Threads made of polyester or synthetic materials are the best match for this category.

Embroidery Sewing Needles

This needle size is optimal for sewing dense embroidery by flexing the fabric up and down at a rapid pace. The embroidery sewing needles have a wide eye to accommodate large threads like polyester, cotton, or polyester.

How To Choose Sewing Machine Needles?

There are two factors you need to consider when choosing the sewing machine needle. The first aspect is the material, size, weight, and thickness of the fabric you want to sew.

Secondly, consider the sewing task and projects you want to carry out. For example, a twin needle is a much better choice for decorative sewing patterns than regular tools.

After addressing these two factors in your sewing project, you can easily pick an ideal needle size and type. Here is a summary of the needle sizes and their compatible materials.

| Type Of Sewing Machine Needle | Size | Fabric Type |

Universal | 70 (10) | Sheers, voile, delicate silk |

| 80 (12) | Poplin, shirtings, light wool, rayon, | |

| 90 (14) | Calico, linen, medium to heavy fabrics | |

| 100 (16) | Upholstery and heavy fabrics | |

| 110 (18) | Upholstery and extra heavy fabrics | |

Sharp | 70 (10 | Microfiber, voile |

| 80 (12) | Microfiber, patchwork, shirtings | |

| 90 (14) | Top stitching for all sharps | |

Ballpoint | 70 (10) | Tricot, light knits |

| 80 (12) | Lacoste, Interlock | |

| 90 (14) | Double knits, medium and heavy knits | |

Stretch | 70 (10) | Elasticized fabrics and light lycra, |

| 90 (14) | Heavier lycra, Elastic, and elasticized fabrics | |

Jeans | 90 (14) | Tigh woven fabrics and denim |

| 100 (16) | vinyl and heavy denim | |

Leather | 90 (14) | All suede and leather |

| 100 (16) | All authentic suede and leather | |

Embroidery | 75 (11) | Decorating lightweight fabrics |

| 90 (14) | Decorating heavy fabrics |

What Do The Size Numbers Of Sewing Needles Indicate?

You can see the numbers 110/18 or 80/12 on a sewing machine needle. As mentioned above, the larger number (ranging between 60 and 120) belongs to the European system, while the smaller one (between 8 and 18) is American.

How Often Should You Replace Sewing Needles?

Switching between your sewing needles for each project is advisable to achieve the highest result. Needles’ prices are not high, and they are available in many sewing accessories stores.

However, a broken or bent needle can cause your sewing machine to jam and damage its electric motor. Therefore, it’s best to check your needles thoroughly before using them.

How To Fit A New Needle?

You should insert a paper piece under the sewing machine’s foot before fitting in the new needle. This practice will prevent the needle from dropping inside the sewing machine when you loosen its screw.

Final Thoughts

Knowing the differences between sewing machine needle sizes is a capacity no sewer can lack. It helps you pick the most optimal needle size for each fabric material with unique characteristics.

While a small sewing machine needle can deliver very sharp and tight stitches, it cannot cope well with a thick and heavy fabric piece. Meanwhile, you have to use larger needle sizes for thick fabric materials and challenging projects.

I hope the provided answer and information in this post can give you more insights into sewing machine needle sizes and their utility.

Thank you for reading!