Why does my sewing machine keep jamming?

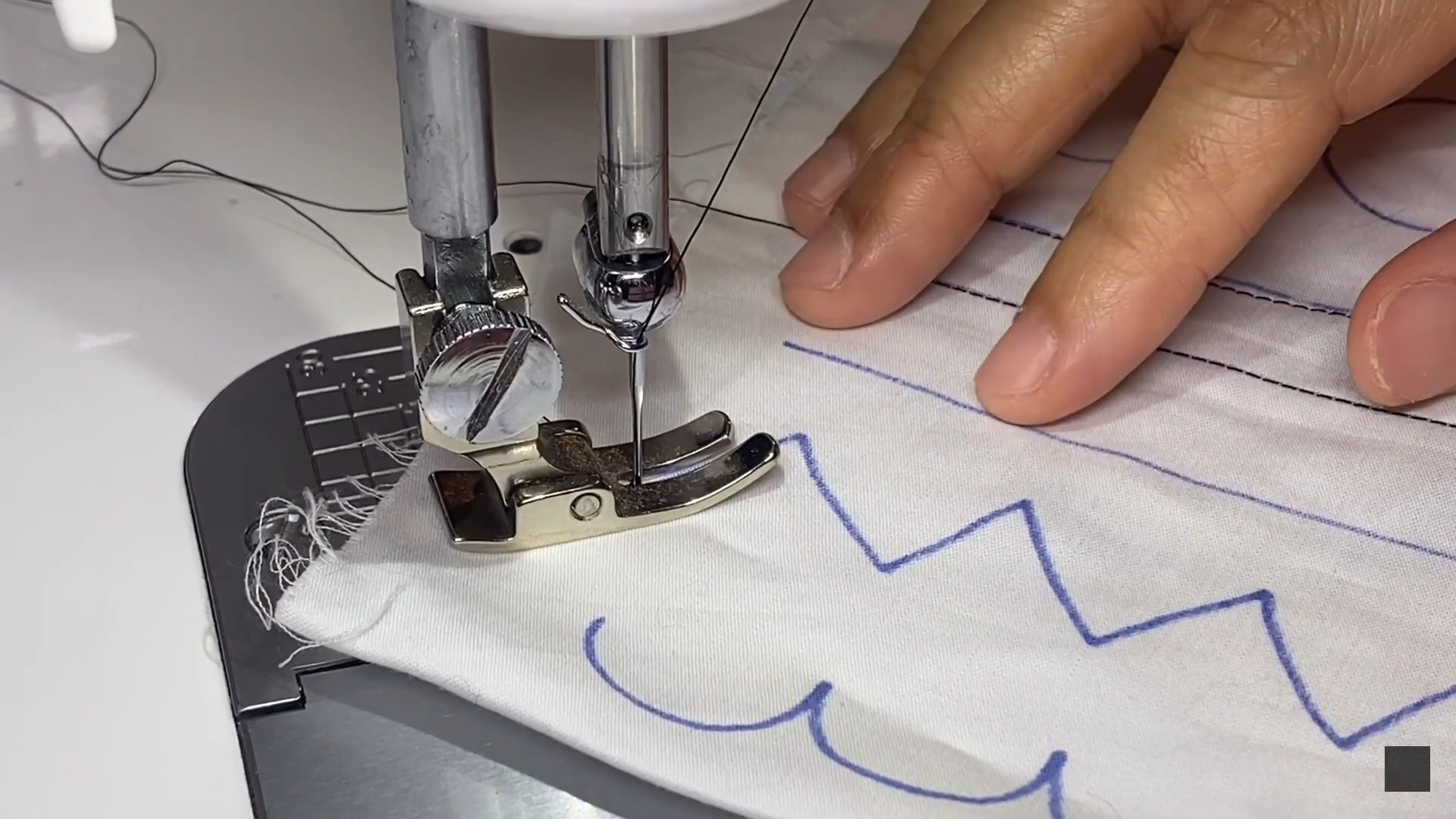

While using a sewing machine, you must have faced at least one situation where the sewing machine is stuck. So why does my sewing machine keep jamming?

This article will help you with the 12 causes below and a fixing guide for each one. So, do not omit any information if you want to stop sewing machine jams.

Table of Contents

Why Does My Sewing Machine Keep Jamming?

A broken small needle or a faulty presser foot can also cause the sewing machine to jam. If your sewing machine stops working unexpectedly, consider the problems below to get the right solution.

- Incorrect threading

- Poor bobbin

- Dirty needles

- Thread tension

- Strange objects on the feed

- Presser foot

- Dirty sewing machine

- Defective sewing

- Handle with a too-thick layer

- Broken Needle

- Congestion at one or more points

- The handwheel does not move

Incorrect threading

Incorrect threading is a common mistake that stops your sewing machine from working. Threading the wrong way will affect the tension, sometimes causing the stitch to be missed.

These problems will often lead to the machine being stuck or stopping working.

Poor bobbin

A bobbin that doesn’t fit properly can also affect tension and seams. Recheck the bobbin position if the sewing machine stops working to solve the problem.

Dirty needles

After prolonged use, lint and dirt will remain on the needle. The more dirt, the less efficient the needle is. The sewing machine won’t even be able to control the hand to work correctly, resulting in some annoying malfunctions.

Thread tension

If the Polyester thread tension on the sewing machine is not enough, it may cause bundles and jams. Meanwhile, if you put the thread too tight, the line is easy to break during work.

Both of the above cases negatively affect the operation of the sewing machine. So, before performing any task, readjust the thread tension according to the job and fabric you are using.

Related: Embroidery Thread Vs Sewing Thread

Strange objects on the feed

The movement system moves the fabric according to the pre-set speed and sequence. However, when there is a foreign object, it will not be able to handle it, causing the movement of the fabric to be affected.

Foreign objects that affect sewing equipment’s operation can be lint and thread. Ensure your movement system is clean and free of unpleasant obstructions.

Presser foot

Propellers are more important than you think. It is responsible for keeping the fabric in place throughout the work.

Yet, it only works if you install it in the right place. If the machine is stuck, check the presser foot and install it according to the manufacturer’s instructions.

Dirty sewing machine

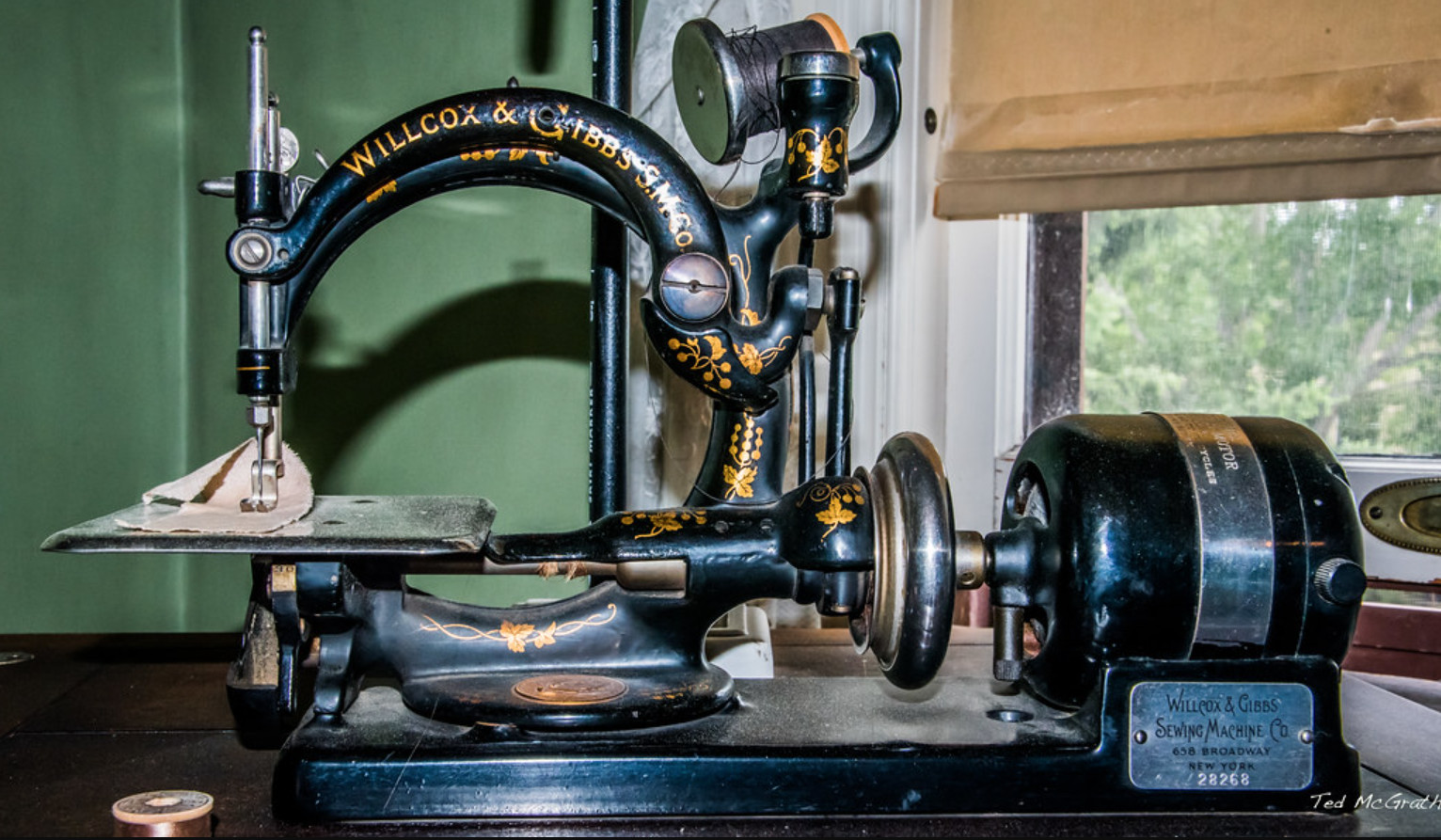

Dirt and lint accumulated over a long time will affect the operation of the sewing machine. You should keep the engine clean regularly and maintain it periodically.

Defective sewing

Malfunctioning parts in the sewing machine are also why your tool stops working. If you are not too familiar with how to repair a sewing machine, you should seek professional repair people to solve the problem quickly.

Related: How to stretch the waist on Jeans

Handle with a too-thick layer

Each presser foot works with different fabric thicknesses. So, with materials that are too thick, jamming may occur.

If you often work with thick fabrics, you should upgrade your equipment to avoid unexpected problems.

Broken Needle

If you often work with sewing machines, you must have faced at least once a broken or bent needle. This condition prevents the thread from entering the fabric, reducing the device’s average performance.

To avoid interrupting the working process, you should replace the needle with a new one. Also, you must prepare the one with the right size for your fabric.

Congestion at one or more points

There are quite a few reasons that lead to congestion at one or more points. For example, with reverse sewing, you will be unable to work efficiently because gears are easy to jam.

The handwheel does not move.

There are two main reasons the needle won’t budge: the clutch disconnecting and the wrong needle size.

If the problem is from the clutch, you should check the hand wheel and adjust the bobbin winder. Meanwhile, you must replace the needle according to the fabric thickness with the wrong needle size.

How To Properly Thread Sewing?

You can refer to the instructions available on the sewing machines or learn through the video threading instructions online. In the section below, I show you the simplest operations to perform threading according to the instructions:

- Step 1: Insert the hollow bobbin onto the spindle, then wind the thread around the bobbin by holding the tip and rotating the bobbin in the correct direction.

- Step 2: Insert the bobbin into the box. Then pull the thread over the tension discs and control the tension to prevent thread duplication or breakage.

- Step 3: Pull the thread down and then push the line into the needle from back to front. Then draw it up; you’ve successfully created a bottom loop.

- Step 4: Repeat the above operations until the line threading task is completed. After this step, you are ready to start sewing.

How To Install The Bobbin On The Machine?

Similar to threading the machine, installing the bobbin on the device will not take much of your time.

- All you need to do is find the correct position to place the bobbin on the sewing machine and then thread the device as instructed above.

- After threading the bobbin, hold and turn the wheel on the side of the sewing machine until the bobbin is full.

- Cut off the excess cord and replace the cover to finish the bobbin installation.

Related: Sewing machine repair services near me

How To Apply Thread Tension?

First, you carefully check out the required tension of the fabric you are dealing with. Insufficient pressure will result in sloppy seams. On the contrary, if the thread is too tight, it is pretty easy to break, affecting the accuracy of the seam.

Next, try tightening or loosening the tension. You will have to do some testing to get the proper pressure. Of course, mistakes can happen, but you will learn to work more effectively after each adjustment.

Final Words

Hopefully, through the information in the article above, you have gotten the answer to the question: Why does my sewing machine keep jamming?

There are many causes for this stuck situation. What you need to do is handle different positions according to my instructions above.

I hope the article is helpful for you. Thank you for reading!